Address

No. 128, Binhe Road, Gongyi City

Zhengzhou City, Henan Province, China, 451200

Contact us

Phone: (+86) 13386837400

WhatsApp/WeChat: (+86) 13386837400

Address

No. 128, Binhe Road, Gongyi City

Zhengzhou City, Henan Province, China, 451200

Contact us

Phone: (+86) 13386837400

WhatsApp/WeChat: (+86) 13386837400

Vertical Shaft Impact (VSI) crushers are designed to be used in secondary, tertiary or quaternary stage crushing. The crushers are suitable for a wide range of applications including the production of high quality manufactured sand, well formed aggregates and industrial minerals. Crushers can also be used for shaping or removal of soft stone from aggregate. VSI Impact Crushers are suitable for manufactured sand, re-crush of slow selling stocks, cubical products fractured gravel, material beneficiation, crushing of cement clinker before mills and glass recycling applications.

DESCRIPTION

Vertical Shaft Impact (VSI) crushers are designed to be used in secondary, tertiary or quaternary stage crushing. The crushers are suitable for a wide range of applications including the production of high quality manufactured sand, well formed aggregates and industrial minerals. Crushers can also be used for shaping or removal of soft stone from aggregate.

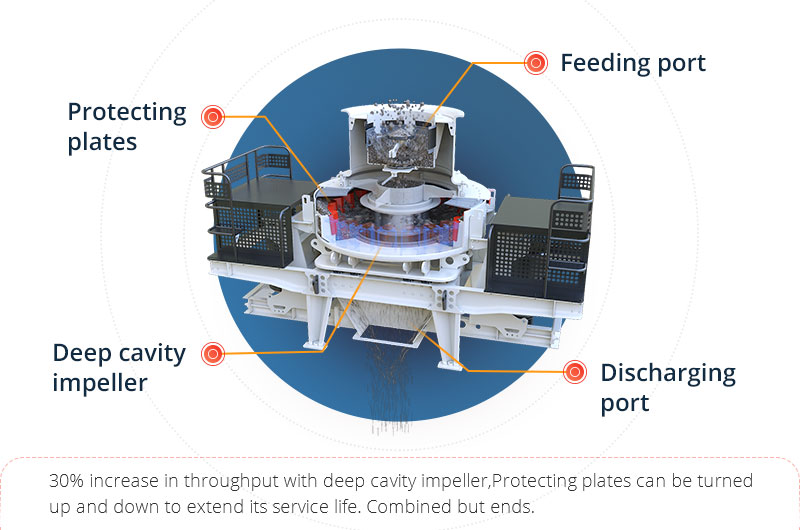

The structure of the sand making machine

The materials fall into impeller with high-speed rotation vertically. On the force of high-speed centrifugal, the materials strike to the other part of material in a high speed. After mutual impacting, the materials will strike and rub between the impeller and the casing and then be discharged straight from the lower portion to form a closed multiple cycles. Final product is controlled by screening equipment to meet the requirement.

The VSI VSI Sand Maker has two types: rock-on-rock and rock-on-iron. Rock-on rock is to process abrasive material and rock-on –iron is to process normal material. The production of rock-on-iron is 10-20% higher than rock-on-rock.

Technical Data of VSI Sand Maker:

| Model | VSI 7611 | VSI 8518 | VSI 9526 | VSI 1140 | VSI 1145 | VSI 1150 | |

| Capacity (t/h) | Feed both at center and sides | 80-180 | 140-260 | 200-380 | 300-520 | 350-610 | 360-650 |

| Feed at center | 40-90 | 70-130 | 100-190 | 160-260 | 180-355 | 190-365 | |

| Max.feeding size (mm) | Soft material | 35 | 40 | 45 | 50 | 50 | 50 |

| Hard material | 30 | 35 | 40 | 40 | 45 | 45 | |

| Rotation speed(r/min) | 1700-1890 | 1520-1690 | 1360-1510 | 1150-1300 | 1150-1300 | 1150-1300 | |

| Motor power(kw) | 4P 110 | 4P 180 | 4P 264 | 4P 400 | 4P 440 | 4P 500 | |

| Overall dimension(L×W×H)(mm) | 4100×2250×2300 | 4160×2320×2900 | 4560×2450×2830 | 5500×2700×3100 | 5500×2700×3100 | 5500×2700×3100 | |

Note: 1. Processing Capacity May Vary With Different Materials And Feeding Sizes.

2. The technical parameters above are not binding, we reserve the right to adjust according to the actual need.