Address

No. 128, Binhe Road, Gongyi City

Zhengzhou City, Henan Province, China, 451200

Contact us

Phone: (+86) 13386837400

WhatsApp/WeChat: (+86) 13386837400

Address

No. 128, Binhe Road, Gongyi City

Zhengzhou City, Henan Province, China, 451200

Contact us

Phone: (+86) 13386837400

WhatsApp/WeChat: (+86) 13386837400

Customized China Jaw Crusher Parts Jaw plate manganese steel casting factory

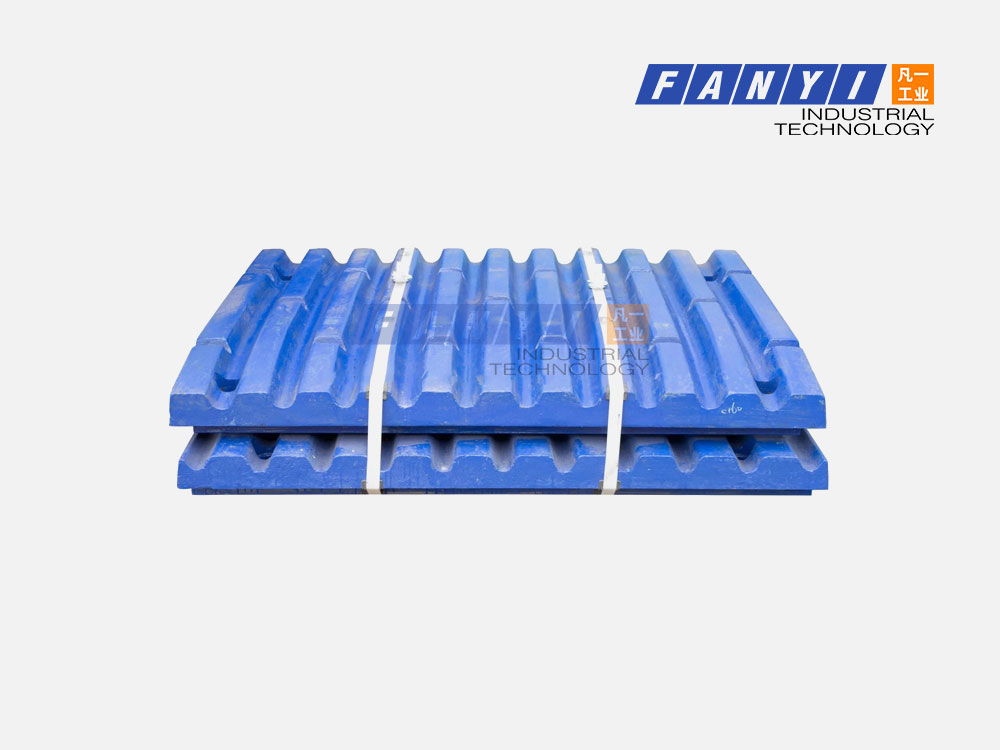

Product Name: Jaw crusher Jaw plate

Applications: Widely used in mining industry, metallurgical industry, construction industry, chemical industry and silicate industry for crushing hard and medium hard ore and rock, such as iron ore, limestone, copper ore, sandstone and so on.

Product Benefits:Compared with the general market products, our products smooth surface, accurate dimensions, high wear resistance and longer life. Direct sales by the company foundry, cost-effective products.

DESCRIPTION

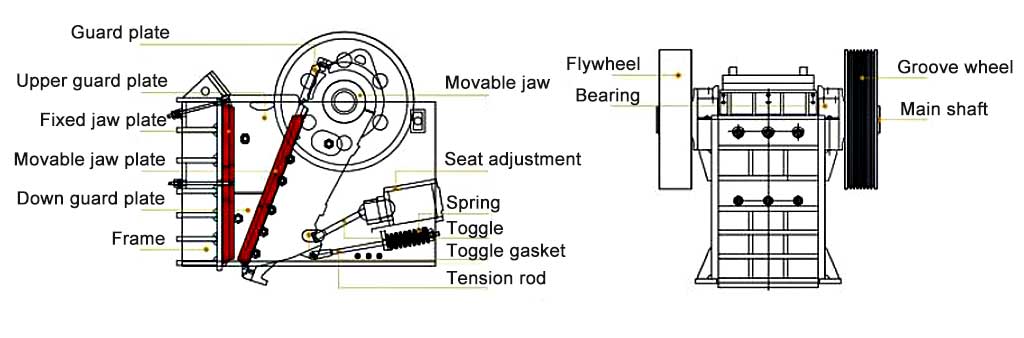

Supply for all kinds of crusher, standard design

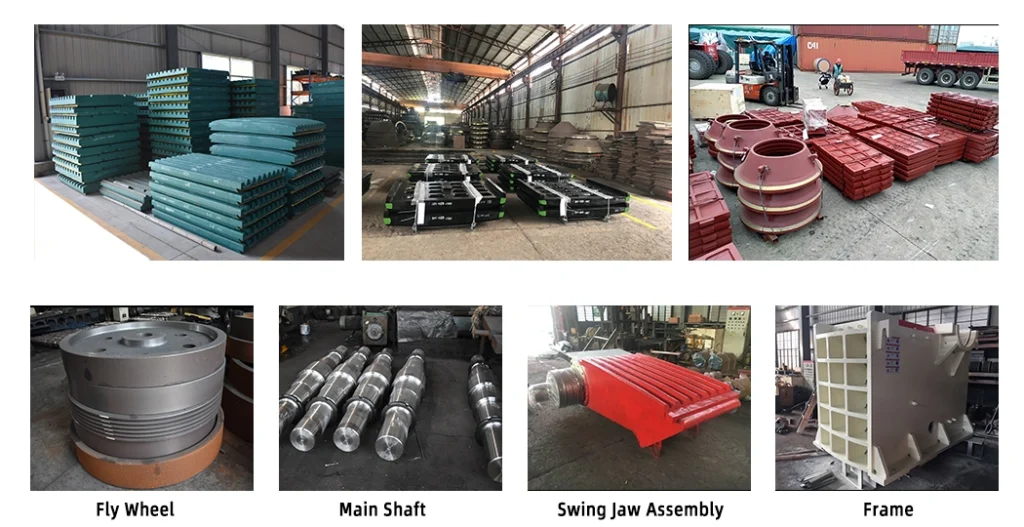

The stone crusher wear parts is the parts contact with stone directly, the wear parts are used in place of all kinds stone crushers, including jaw crusher wear parts, impact crusher wear parts, cone crusher wear parts, vertical shaft crusher wear parts, stone crusher wear parts and etc rock breaker parts price

Movable jaw plate, fixed jaw plate, side plate and etc for jaw crusher. Impact plates, blow bar and V-elt for impact crusher, screen mesh for vibrating screen, rubber belt, rollers and etc for belt covneyor, blade, runner plates for sand making machines.

Our versatile jaw plates, spanning from Mn13Cr2 to Mn22Cr2, cover diverse applications and feed materials. Tailor-made to your needs, our customized jaw plates ensure optimal performance.

| Jaw Crusher Parts | |||||||

| SANDV1K | N0RDBERG | PE | KUE-KEN | Pegson | POWERSCREEN | TEREX | |

| CJ208 | C80 | LT80 | PE250*400 | 104 | 600X400 | 900X600 | JC2236 |

| CJ209 | C96 | LT95 | PE400*600 | 105 | 700X500 | 900X600HA | JC2248 |

| CJ211(J11) | C100 | LT96 | PE500*750 | 106 | 800X550 | 1100X650 | JS3042 |

| CJ408(JM806) | C106 | LT100 | PE600*900 | 107 | 900X600 | 1100X650HA | JS3054 |

| CJ409(JM907) | C110 | LT105 | PE750*1060 | 108 | 1100X650 | 1100X650HR | JC4248 |

| CJ411(JM1108) | C116 | LT106 | PE870*1060 | 114 | 1100X800 | 1100X800 | JC3660 |

| CJ412(JM1206) | C120 | LT110 | PE1200*1500 | 118 | 1200X450 | XA400 | JC5460 |

| CJ612(JM1211) | C125 | LT116 | PE1400*1800 | 120 | XR400 | ||

| CJ613(JM1312) | C140 | LT125 | PEX250*750 | 120S | XA400S | ||

| CJ615(JM1511) | C145 | LT140 | PEX250*1000 | 120M | XA750S | ||

| CJ815(JM1513) | C160 | LT145 | PEX250*1200 | 150 | |||

| CM1208i | C200 | LT160 | PEX350*700 | 160 | |||

| CM1208F | PEX300*1300 | 200 | |||||

| CM1211 | 200SD | ||||||

| CM1511 | |||||||

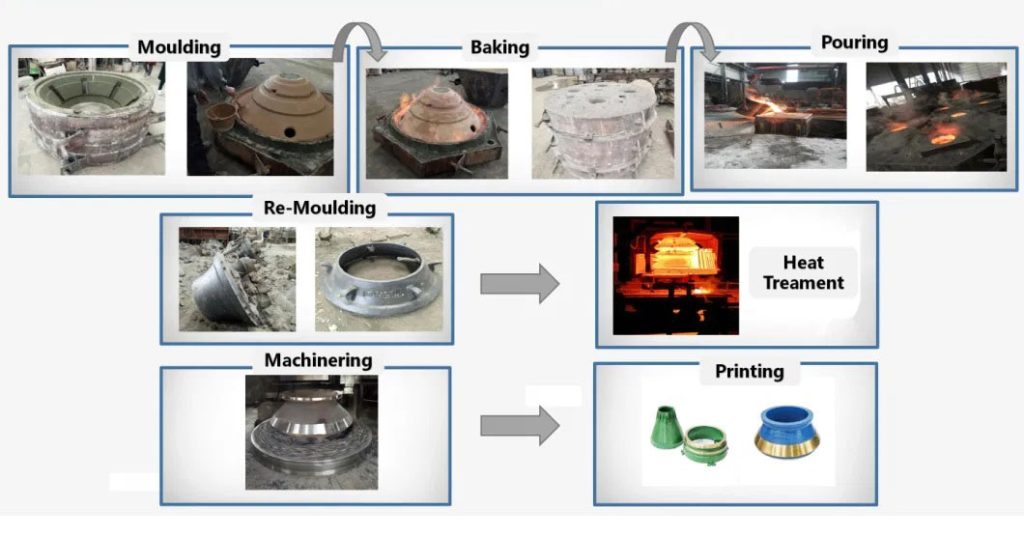

1. Which material can be supplied?

2. What do you manufacture there?

3. How large is your facility? Which types furnaces do you have?

4. What temperature is the casting when it enters the heat treatment furnace?

5. What information do we need to provide to you in order to confirm our parts order?

6. How long does it usually take for me to receive the goods?

7. How do you deal with quality problems?