Address

No. 128, Binhe Road, Gongyi City

Zhengzhou City, Henan Province, China, 451200

Contact us

Phone: (+86) 13386837400

WhatsApp/WeChat: (+86) 13386837400

Address

No. 128, Binhe Road, Gongyi City

Zhengzhou City, Henan Province, China, 451200

Contact us

Phone: (+86) 13386837400

WhatsApp/WeChat: (+86) 13386837400

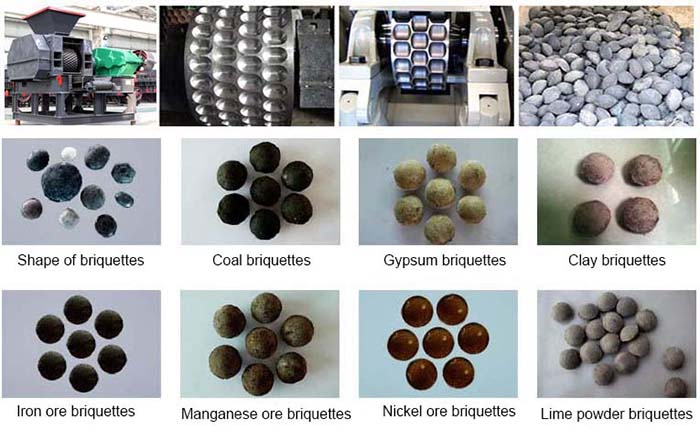

A briquetting machine, also called a briquette press machine or briquette-making machine, is a device that converts powdered or granular materials into larger, more convenient shapes called briquettes.

According to materials, there are 5 most popular briquette machines at present: charcoal briquette machine, coal briquette machine, metal powder briquette machine, lime briquette machine, and gypsum briquette machine. They are popular for their unique properties, applications, and reasonable prices.

DESCRIPTION

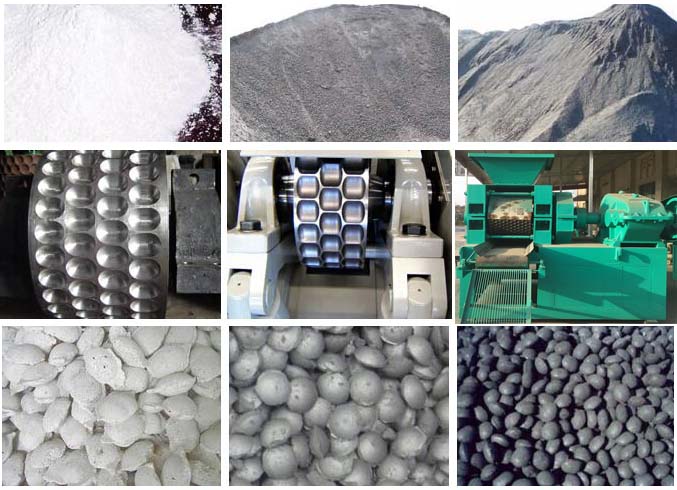

Standard Briquette Machine, with other names of briquette machine, briquette press machine and briquette making machine. The briquette making machine or briquette press machine can be used to press various powders, scrap, waste residue such as pulverized coal, iron powder, coking coal, aluminum ash, iron filings, iron oxide scale, carbon dust, powdered carbon, slag, gypsum, gangue, sludge, kaolin, active carbon, coke breeze and so on. The briquette press machines are widely used in refractory, powder plant, metallurgical, chemical engineering, energy, transportation, heating and other industries. The molding materials that made by the briquette making machine are energy conservation and environment protection and easy to carry. The briquette machine also improves the utilization rate of waste, which has significant economic benefits and social benefits.

The roller sheet of the briquetting machine is cast by manganese, the hardness of which can reach up to 58 degrees after special processing. Because the roller sheet adopts combination assembly, it is adjustable after abrasion. The buffer device in the briquette machine can protect the equipment from being impacted by the hard object to a certain extent.

The briquette machine uses main motor to transmit the motive power to speed reducer through the V-shape triangle belt and to main drive spindle through coupling, and then uses the main driven split gear to send it to the main driven spindle to make the two rollers fall into step (inverted running with uniform speed).

The driven roller is held by the piston of the hydraulic oil cylinder, the hydraulic system completes the circuit and the control valve in the hydraulic system keeps the system pressure. Materials are entered evenly into the feeding hopper of briquette machine through the rationing equipment, and then poured into the breaker rolls evenly adjusted by the regulating sluice. The two big rollers push raw materials with high pressure force, to press them into briquettes, and successfully complete drop from rollers.

| Model | Roller Dia.r ( mm ) | Roller Width ( mm ) | Roller Material | Shaft Speed ( r/min ) | Reducer Model | Pressure Form | Motor Power ( kW ) | Capacity (t/h) |

| YQJ-290 | 290 | 200 | 65Mn | 18 | ZQ350 | Constant Wedge Pressure | 5.5 | 1-2 |

| YQJ-360 | 360 | 250 | 65Mn | 18 | ZQ400 | Constant Wedge Pressure | 7.5 | 2-4 |

| YQJ-400 | 400 | 250 | 65Mn | 18 | ZQ400 | Constant Wedge Pressure | 11 | 4-6 |

| YQJ-500 | 500 | 300 | 65Mn | 13 | ZQ500 | Constant Wedge Pressure | 18.5 | 6-10 |

| YQJ-650 | 650 | 336 | 65Mn | 13 | ZQ650 | Constant Wedge Pressure | 30 | 10-15 |

Note: 1. Capacity May Vary with Different Materials and Feed Sizes.

2. The technical parameters above are not binding, we reserve the right to adjust according to the actual need.

| Model | Roller Dia. (mm) | Roller Width (mm) | Motor Power (kW) | Shaft Speed (r/min) | Reducer Model | Capacity (t/h) | Pressure Form | Roller Material |

| YYQ-476 | 476 | 210 | 22/1.5 | 15 | ZQ500 | 3-6 | Hydraulic Pressure | 65Mn |

| YYQ -476 | 476 | 260 | 30/1.5 | 15 | ZQ650 | 4-8 | Hydraulic Pressure | 9Cr2M0 |

| YYQ -500 | 500 | 300 | 30/1.5 | 15 | ZQ650 | 5-9 | Hydraulic Pressure | 65Mn/9Cr2M0 |

| YYQ -650 | 650 | 336 | 45/1.5 | 15 | ZQ750 | 8-15 | Hydraulic Pressure | 65Mn |

| YYQ -672 | 672 | 275 | 75/1.5 | 13 | ZQ1000 | 8-15 | Hydraulic Pressure | 9Cr2Mo |

| YYQ -750 | 750 | 400 | 55/1.5 | 13 | ZQ850 | 15-20 | Hydraulic Pressure | 65Mn/9Cr2Mo |

| YYQ -850 | 850 | 500 | 75/1.5 | 10 | ZQ850 | 20-30 | Hydraulic Pressure | 65Mn/9Cr2M0 |

| YYQ-1000 | 1000 | 650 | 110/1.5 | 10 | ZQ1000 | 30-50 | Hydraulic Pressure | 65Mn/9Cr2M0 |

Note: 1. Capacity May Vary with Different Materials and Feed Sizes.

2. The technical parameters above are not binding, we reserve the right to adjust according to the actual need.